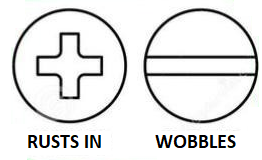

Philips screws are awful. They strip if you look at them wrong. Flatheads should only be used on thumbscrews just in case you need a little extra torque from a screwdriver.

Torx and Hex are excellent.

I work on electronics and woodworking and Phillips are the utter worst of both of them. The thread lock in computers makes them easy to strip when unscrewing. The resistance of driving them into wood makes them guaranteed to strip when screwing. Fuck them.

The big issue I see with people driving Phillips screws is that they don’t use a large enough driver size. Computer screws for example are Phillips #2 and I’ve never had an issue with them stripping.

I use the correct driver, I’ll go through my kit to find the best fitting bit. It simply comes down to the fact they are designed to strip to avoid “catastrophic failure”. Plus the fact that companies use intentionally cheap, soft screws, to make repair and service harder. Cough cough zinc screws on a $10,000 iMac (steel screws would have cost 25 cents for 10, zinc like 5 cents for 10, fucking ridiculous).

I read that the thing about them being designed to strip to prevent worse failure is just a myth. Or at least they weren’t originally designed to. It said that the original patent never contained any feature for that. Wouldn’t surprise me though if modern companies do use screws designed to strip to prevent disassembly/repair.

I think originally the screws would cause the driver to cam out and stop driving if a certain amount of force is applied but the screws are so soft and cheap that the harder driver damages the screw head when it cams out.

This and the centered shape that Philips and Robertson have were key. The lack of a sharp driver bit being able to slip out of the fastener prevented a lot of injuries.

However, Philips, at least, needs to go away.

I always figured it was intentional but for the other reason: screws soft enough that overtightening can’t damage/crack the multi-thousand dollar components, the screw head cores out first.

That’s great, but then you can’t get your multi-thousand dollar component unscrewed anyway so what was the point?

It’s also a design flaw that it’s so easy to use the wrong sized driver and it will sorta work. It might be annoying that you have to have a set of different star drive or hex drive bits, but you’re less likely to strip them.

Maybe I’m just being lucky but I’ve never experienced screws stripping anymore since I’ve started getting better tools for myself.

And in woodworking it can also help to pre-drill a hole using your smallest drill, before screwing a screw in. This also prevents the wood from cracking. I’ve also seen wood screws that have some lubrication pre-applied.

The problem is, when working with electronics, you can have a great screwdriver but it won’t help if the screws in the device are very cheap (and probably partially stripped already from someone opening it previously).

I swear I’ve had stuff with stripped screws right from the store.

I’ll be honest that I’ve never really experienced problems like that before. I’ve had cheap screws and partially stripped screws. But so far I’ve always been able to open them with the right screwdriver.

But I believe you when you say you did and maybe you have a lot more experience than I do so I’ll respect your opinion.

I haven’t had any completely fail yet, but I’ve seen some come worryingly close. I don’t really have all that much experience, but from what I’ve seen it just doesn’t seem like the most reliable design.

PC fan screws come to mind because they are self tapping and a lot of people seem to not use the right screwdriver or don’t yet know the trick of running the screws in and out of the fan one time outside of the case first.

Could be that it’s not a Philips but a JIS. I didn’t even know that JIS existed until a couple years ago. The shape is close enough to Philips to mostly work but make it super easy to strip.

Torx gang unite.

We had our 20 y/o deck repaired and stained last year. I was chatting with the overseer about what he was going to do and the topic of screws came up; he said he was going to use Torx, and only ever used Torx anymore - I just about cheered.

I’d been losing hope in humanity lately, but little signs of sanity like this, professionals finally getting rid of the hell-bits that are Phillips heads, lifts my heart and gives me hope.

These days, all but the cheapest outdoor-grade screws in the US are torx, generally with a bit thrown into the box that, while cheap, should work fine for a few boxes’ worth.

Freaking awesome. Better and better. We’ve finally fixed the screw heads, and pretty much also computer connectors (and small device chargers!) with USB-C. Just in time for the end of the world via total ecological collapse.

Great times.

I work at a big box hardware store, and I can confirm that almost all deck and structural screws are moving to torx. (much to the older generations dismay)

That’s what a worker at my local Ace store said: they were slowly transitioning to Torx.

I’ve heard that was more of a European thing, but the only two serious contenders are Pozidriv vs Torx for screws (and hex vs Allen for bolts).

I just checked my local hardware store’s website, and out of the 176 kinds of 4/4.5mm screw boxes in their inventory, 74 are Torx, 55 are Pozidriv, and 38 are Phillips (ew).

Either Torx or Pozidriv is fine when used properly, however most DIYers don’t understand the difference between PZ and PH and end up stripping their heads. Also it’s much harder to use the wrong-sized bit with Torx than PZ.

So yeah, Torx wins in just about every category and other heads only get manufactured to appease old people and penny-pinchers.

That’s one of my issues with Pozi - it can be hard to see the markings, and not everyone has great eyesight. I mostly object to Phillips-related screws because there are so many variations that mostly look the same and require a table to differentiate. And none have the torque-transfer performance of Torx. Plus, you can use a hex head in a Torx bit in an emergency and you don’t much care about either the bit or the head.

I’m not sure I’ve ever seen a philips or slotted deck screw. I have and have purchased many boxes of these things and they’ve always been nearly 100% Robertson. Is this a US thing?

Yes, and you’re Canadian. Robertson is the standard there, and while it’s used in other countries, not nearly as much.

In the beginning was slotted heads, mainly because mass machining and casting wasn’t good enough to have more precise forms. Then came the Great Connector Wars, and in the US the Phillips head won and was standardized; almost every house built in the US in the past 80 years will be built with these (and nails). Slotted heads are much less common, but you find them in various specific places, like where the heads are visible and you want to hide the screw as much as economically possible.

Canada, however, was smarter and standardized on the Robertson head; IIRC one reason for the divergence was the Phillips licensing cost. In any case, Robertson is superior to Phillips in most ways, except it’s even worse to dig out if it gets painted over.

As machining improved, many attempts were made to improve on Phillips, which mostly amounted to polishing a turd; Robertson remained unchanged as it was already pretty good.

Then came hex, which is great except it’s structurally pretty terrible for the head. Still, it can be seen as an improvement in Robertson, but not quite so good as to be worth all the retooling. Good enough that it’s probably the second, or at least third, most popular head in the US.

Finally, someone did some fucking math and came up with Torx, which is provably and demonstrably superior to all other screw heads. It maximizes force transfer, and leaves more material in the head; it’s harder to strip out, and can be applied effectively to very small screw heads. There’s a security version, which was mostly useless (for intended purpose) the day after it was released, but beyond that, there’s no real improvement that can be made.

The Phillips patents expired decades ago, so it’s holding on mainly from inertia. Commercial contractors don’t have much invested in it, because they have to literally buy boxes of replacement Phillips heads because of how shitty the design is and how often the heads break. While manufacturers have a steady stream of revenue from selling replacement Phillips tools that have broken, this is balanced by the mouth-watering prospect of every contractor in the US buying new Torx size-sets and high-end Torx tools. And the screw makers probably DGAF as they’ll sell screws either way; Torx screws might be a little more expensive - they used to be, but I haven’t compared lately.

Canada may just motor on using Robertson; there’s less incentive for them to retool since Robertson isn’t nearly as crappy as Phillips, so the cost/benefit to upgrade to Torx is less compelling. But who knows?

Flatheads should only be used on thumbscrews just in case you need a little extra torque from a screwdriver.

The only other legitimate use I’ve seen for flatheads is on wooden boats, where you’ll be gooping the head up with tar for waterproofing. Since you’ll eventually have to scrape it back off again to get to the fastener, you want a simple geometry that’s easy to clean.

The image feels like it should be posted in c/unpopularopinions

Square (Robertson) drives are actually great too. Better than Hex/Allen, but Torx is the most reliable, and the most German. Phillips can take a long walk off a short pier.

I do wish Robertson heads were more common. They’re almost as tough as torx, but tapered to stick on the tip of the tool, which is so convenient.

The ones with bumps in the middle can go fuck themselves

Square is nice too but square/Phillips is a good damn lie. Because the Philips side of it doesn’t work well enough so it is still just a square but with extra slots

I feel like spanner would be the best for not having shit getting stripped. But that’s just looking at this diagram; never seen them IRL.

They’re mostly just used for tamper-proof screws for things like bathroom stalls so people can’t take them apart as a “prank” or whatever. The screw driver bits tend to break easily, which is usually worse than the screw stripping.

Hexagons are the bestagons

Fuck this. Torx, Hex, square drive are all positive engagement. Phillips is literally designed to cam out. Slotted is just the first head type to have existed because of how easy it is to make, but is far inferior to every other type.

A good square bit for my impact is a lifesaver as an electrician. Pretty much every conduit fitting set screw can take flat, Philips, or square. When you’re reaching out one-handed from the top of a ladder, you really don’t want to cam out all the time.

Is it just a Canadian thing to call the square head a Robertson?

Red robby, green robby.

Flat head screws are necessary when at a very small scale like in watchmaking.

deleted by creator

Robertson (square) is also great, and it’s as Canadian as bagged milk

Torx were basically invented because Henry Ford wanted to have exclusive use of the patent for robertsons and the Canadian didn’t want to do that.

Henry Ford was a terrible person for so many reasons, but this one really pisses me off.

Really not a fan of Hex (it just cams out way too easily) but Torx is like screwdriver orgasm. Philips just feels like intentionally bad design

Philips just feels like intentionally bad design

Philips are designed the way they are so that they “cam out”. Meaning if too much force is applied to the screw, the driver will intentionally pop out to avoid damaging the tool or the fastener. Its a feature, not a flaw. A Robertson (square), torx, or hex will let you apply enough force until the screw or the driver fail catastrophically.

Maximum ugga duggas!

The Robertson, being a Canadian invention, appropriately allows the “full send” method of applying force.

As an American who has only worked with Robertson once, it was the best thing ever. Just so easy to work with. Even better than torx.

Built my deck w/ squares & it was way faster than any other type of screws I’ve used before.

Philips are designed the way they are so that they “cam out”.

Which is why Philips are so great for drywall screws. They shouldn’t be used to anything else though…

If you’ve tried to do any large amount of work with slotted, you’ll know that it belongs in Mental Disorders. I’ll take Six-Lobe/Torx over phillips or slotted any day of the week.

Yea but fuck the security torx screws. Also hot take, but underrated screw goes to tri-wing/Y. They’d be great screws if they weren’t security screws as well.

Also hot take, but underrated screw goes to tri-wing

Is that a hot take? Everyone I’ve ever mentioned them to who knows what they are immediately starts shit talking both them and Nintendo for making us buy a screwdriver for one set of devices in our lives

I remember melting plastic pens onto the nintendo screw heads in order to get them out. Fun times.

You can just get a pack of security bits from HF or online.

deleted by creator

Wow, person making this chart actually has no clue. First two are absolute worst nightmare. Torx, Pozidrive, JIS, Alan all great with minimum damage.

It’s the “grandpa has been using slotted all his life so it can’t be bad” reasoning. I can’t think of a single use case I’d want slotted or even philips, if I’ve got a choice. Torx or bust!

If you’re having trouble with Torx, buy better screws and bits. There are so many terrible screws around. The difference between a deep well fitting head and the cheap trash is massive.

Yea, I had quite the wtf moment one time when I stripped a Torx screw.

If you’re having trouble with Torx, buy better screws and bits.

Last year I needed to do some hardwood construction outdoors. On the advise of a carpenter I ordered some high quality stainless steel Torx screws online. They don’t sell these in the consumer-oriented DIY store. They were awesome, much harder than the cheap screws, that would easily bend when driven into hardwood, much sharper as well and if you buy a box of 100 or more it comes with a bit which fits perfectly. So much easier to use than the overpriced crap from the DIY store.

Where are people buying shitty tor screws from? Walmart? Aldi?

I’ve only bought them from supply houses or home depot/lowes, and deckmates are a pretty damn good brand.

Karwei or Praxis. Especially their store brand is crap. Rotadrill screws are okay, but not as good as Spax, which they don’t sell.

Are those names of alien races in Star Wars?

Cantina music intensifies

Most of us are dealing with screws that someone else installed, though. Can’t really control the fact that the manufacturer decided to save .5 cents per units by using cheapass screws that strip if you look at them.

slotted screws are all fun and games, but if they’re ruined…you will never get them out. I coursed these screws. Eventually they got the dremel treatement.

Can’t say I’ve ever had fun with slotted screw.

Yes!

You can tell a shitpost is a shitpost when it is entirely wrong

Successfully baited 200 comments

Did you really shitpost? Or did you go fishing?

Was indeed a big catch

Agreed, Phillips needs to get Thanos’d.

Same with slotted, hate them with a passion, especially when it’s those with the raise head

Yeah, they’re literally made to cam out.

Useful for automation, but terrible for repairs.

And the automation argument isn’t as important now that electric drills all have clutches.

I also watch AVE, but it’s Philips heads that were made for early assembly line use to cam out under torque. Specifically for the Model-T if I remember correctly.

Never watched AVE, I used to be an auto tech.

The Wikipedia article has an interesting summary.

Looks like it wasn’t intended by the initial patent, but was discovered as a useful property.

Slotted is absolute shit. Philips is acceptable if you must live in the 1900s.

Torx all the way. Every other type should be illegal and punishable by death of perpetrator’s extended family.

Robertson, or square is the best. Screw will literally stay in the screw without dropping.

Pozidrive and torx ftw. The rest can bugger off tbh.

Also, temper proof torx makes me lol. Brb, grabbing pliers to break of the temper proof bit hahaTemper proof torx makes me lol, because almost every bit set I own includes them.

If you break it off you will most likely leave some behind, which will significantly reduce the mating area because you cannot insert the bit fully and may lead to stripping the screw.

Fair. It all depends on where it breaks off and how tight the screw is. In electronics the screws arent in very tight, and breaking it off often breaks it off all the way down to the base.

Whatever happens, tamper proof is a huge fail and a good joke

This is the way

the only slightly justifiable use of slotted is something like the face plate on a light switch or power outlet, where it doesn’t have to be particularly tight and it’s nice you can remove it in a pinch with a fingernail or dime.

… but really if someone came and replaced all of mine with torx I can’t say id complain, so its not like they’re good in that use case… just less awful

Posidrive is an alright compromise. It’s drives fairly well with the correct bit, but will also work with a Phillips screwdriver.

but will also work with a Phillips screwdriver

Only if you hate the screw and never want to see it in its full glory again.

A screwdriver - not a drill or impact driver. For those I always use the correct bit. But the $1 Phillips driver in my desk isn’t gonna over-torque a posidrive.

I’m sorry, calling Robertson “square” is insulting to a superior screw design and fuck you for even pretending it isn’t.

6 “lobe” is torx too. Nobody calls Allen bolts hexagon either.

I don’t think I’ve ever heard that fastener called an Allen bolt, just the tool (Allen key). I’ve generally heard them called hex sockets heads. Maybe it’s a regional thing?

Allen is a brand name, they’re hex keys/wrenches

Yeah you are right

Positive affirmation 🥰🥰

Fun fact speaking of regional things, in Swedish they are called “insex” (as in six on the inside)

In Dutch they are called “inbus”, which apparently comes from the German name “Innensechskantschraube Bauer und Schaurte”, where Innensechskantschraube means inside six sided screw and Bauer und Schaurte is the company who patented the screw type.

I have no idea how the name inbus came to be

Innensechskantschraube Bauer und Schaurte probably

Well yeah but still, who would think of that?

Germans apparently

Maybe, I do hear hex a bunch

Just rude, really.

Agreed, but I often hear Allen keys referred to as hex keys. I don’t think I’ve ever seen anyone confused by that though.

Nobody calls Allen bolts hexagon either.

That’s not true when working internationally, since it can have different names in different nations. In Italy is Brugola, in Germany Inbus and in other places it has other names. Everyone understands what a hex key is though

It’s a crime against safe screwing to dis Robertson like that.

Everyone who does not want torx and nothing but torx has never screwed torx screws.

Honestly, I dont understand why everything isnt square drive.

its simple, and its a pretty strong design that resists camming out and rounding off.

Fuck large format torx that are exposed to the element. I just weld a nut on them now and pound them out with an impact because you’ll break 2 torx bits for every one bolt you’d get out.

There is one screw on this chart that I have a mortal hatred for. Just one. That being the fat Phillips (called “Phillips/square” on this chart meme thing).

I have no idea why, but some companies can’t resist the sadistic urge to put tiny versions of these fuckers on equipment that should just use a torque or Phillips screw head. But no, they want you to truly suffer. Because they don’t stop there: they make the fragile little fuckers out of NICKEL. Which means they are extra malleable and prone to strip if you so much as look at them the wrong way. So imagine you need to replace a hard drive on a RAID-type storage pool that’s already down two spares and you can’t fucking get the drive out of it’s sled because the vendor not only hired a bodybuilder to tighten the screws, but simultaneously chose the worst possible metal just for giggles and chose the screw head that they no body will have the proper bit for and will inevitably use a normal phillips on until it strips.

I now have a ritual procedure of putting every drive that gets replaced in the coldest cold aisle in the datacenter for at least 5 minutes just to make these fucking screws less likely to ruin my day.

Fuck whoever invented the fat phillips, even the lowest ring of hell is too good for them.

But no, they want you to truly suffer.

It’s called Planned Obsolescence, sweatie. Now go out and buy a new device.

Buddy. I’m not talking about consumer equipment. I’m talking about enterprise equipment that costs more than your car. Step off.

And yes, I know planned obsolescence is a thing in enterprise. But that doesn’t mean your enterprise customer won’t make purchasing decisions based on the quality of such small components. We refuse to order from HPE, to give you an idea of how we take this sort of thing. We know what we’re buying and how to use it and if we can’t properly maintain it because the vendor is an asshat, we’ll find a new vendor because fuck you we can’t afford to put up with your shenanigans.

Ya. Just those guys, and anybody who eats turtles. Keep the psychos out of the nice parts of hell.

Every awkward fascist, sexist turtle will be gathered into an imaginary pot and cooked alive for all to see. The aroma and broth will be delectable.

If you have no idea what any of this means and no idea why I don this weird username, then I kindly implore you stay out of it for sake of your own sanity. Otherwise, lmk and I’ll begrudgingly curse you with knowledge of the tale of a particularly disgraceful misanthrope and an even worse excuse for a human being.

A lot of those wacky screws exist solely to keep people from randomly messing with them. You have to really go out of your way the get the right tool for the job, and that’s if there even is one.

Like the one-way screws holding together bathroom stalls.

Those screws can fuck right off. Almost every bathroom stall installed today uses a security torx tip.

Edit: Forgot to clarify, the one way slotted screws can fuck right off.

Yup, I’ve noticed that spanner screws (the two dots) are usually found on elevator control panels. There is no reason that somebody should be able to open those up with a Swiss army knife.

It’s funny because I’ve opened those screws on something else using a bit of effort and the scissors on my swiss army knife.

Socket (hexagon) and Robinson (square) are hyper common standards. You use Robinson for wood working due to the shape offering more resistance for high speed driving, and you use a socket with an allen key in order to get precise high torque hand tightening. IMO Phillips and Slot are the worst common standards due to stripping and sliding.

I agree, but I always thought they were Robertson head screws. Wouldn’t be the first time I was wrong though…

You’re not wrong, and your instance makes me think you’re perfectly aware of this. Be bold, Canadian friend!

Robertson gang rise up! Also they actually hold screws without a magnet (although you probably know that).

I’m not Canadian myself, but I did know that. Other than some cheaper ones being a bit weak from the large-ish chunk required for the square-drive, they’re really great. Much more pleasant to use than Phillips.

I’m American and even i can agree Robertson are the goat.

Phillips and flat suck. Not enough surface area on Phillips, resulting in stripped screws. And getting centered on flat sucks.

Robertson drive, just pop your driver in and it’s self centering, lots of surface contact to drive, and lots of meat on the head to prevent stripping. Anything more than 4 edges is unnecessary.

You are now an honary Canadian.

Where my hex fans at?

Torx crew represent!

Fuck yea

Square Drive Gang would like to battle!

Fuck yea.

❤