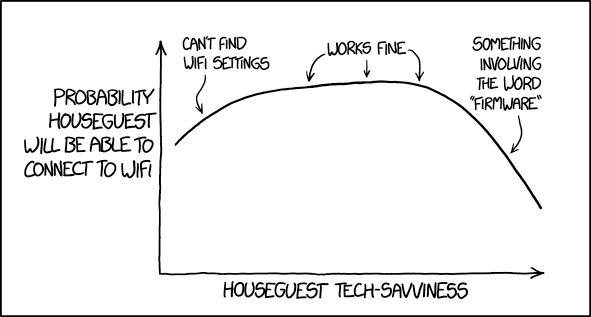

Shoudn’t it be 25%?

Current is not controlled here, resistance (aka the soldering iron) and voltage are.

Power = Voltage ^ 2 / Resistance. Double the voltage, that quadruples the power. So you only want to plug in 25% of the time to get the equivalent power of 120V.

But it might not melt at double power? Maybe the extra heat helps, I can’t find a resistance/temperature curve for a soldering iron…

Source: EE dropout.

nnnNNEEEEEEERRRRRRRRRd!

Right you are. Oops.

If only the oop was here to see this 😔

In my defense, I’ve been helping a friend with an EVSE install where the load (electric vehicle) is smart. In that context, it’s just voltage X current capacity of the line = power. The rest of the story is true as far as I know.

What are you lookin at

I sure hope someone will be fired for this obvious blunder

If my company fired people for trade show cock-ups we would change the entire staff every couple months. There is a lot of stuff being moved in a short time period, shit is stressfull and you’re working at a diminished capacity at least a week aferwards. As long as the stand is not on fire during the show, all is good.

Oh, absolutely. I was just making a bad simpsons reference

Ok. I was acountless on lemmy for a long time, your comment made me finally register. Thanks!

So, yeah, with double the voltage you get 4x the power. But you you put 4 times the power at 50% of the time, you get only 2x the power. And the other half of the time, you get 0 power. On the average you get the same power output.

You double counted there.

You said 4x power 50% of the time and then said “the other half of the time.”

So you’re calculating 50% of 50% which is 25% duty cycle.

Oh no, I didn’t. Should I draw a graph? Pop out some equations?

Let’s say P is the nominal power. When I said “The other half” I meant when the solder iron is not plugged. So:

50% of the time at 4xP 50% of the time at 0…

Oh shizzzz, you’re right!

I imagine this is more or less what it felt like to be in the room at the time. A whole group of people discussing electrical theory and optimal soldering techniques and meanwhile the one guy standing there holding the actual device notices the power cord is a little loose and pushed it in another 1/8" without mentioning it because everyone is so involved in their nerdy conversation.

Oh man I was going through it in my head too…

Also, welcome to Lemmy!

thanks!

I had to think about it too, lol. This is an equation for DC/instantaneous power, and if you want to get into AC math, this is more like a square wave. Averaging the power out over time doesn’t necessarily work with the equation, as you figured out, as it doesn’t when you try to measure AC (sinusoidal) power by average voltage or whatever.

There are gas powered soldering irons that are essentially lighters with metal around the flame. Real life savers

There are also battery powered soldering irons.

I like the pinecil, usb-c powered soldering iron with temperature control. If you are not doing anything intensive any fast smartphone charger will power it.

I’ve had mine running off of a power bank before too.

My TS101 doesn’t really work with a phone charger, I use the laptop’s or a power bank

Depends on the charger and or cable. Might not support the right protocol or just be weird when it should work.

Removed by mod

Yes, and they actually have a working thermostat, so they aren’t complete garbage to solder electronics with.

Gas powered soldering irons are great for soldering stuff like copper water pipes. But even soldering through-hole components with them is a pain in the ass due to the temperature instantly evaporating all your flux. Soldering SMD components is near impossible with them

It’s only stupid if it doesn’t work

And vice versa

Yeah! “It’s only doesn’t work if it stupid.” 🤷♂️ I’ve always said that…

It’s only work if it doesn’t stupid.

deleted by creator

New manufacturing hack unlocked: Install 240v outlets at workstations and fire half of the workforce. Golden parachute and douchey, hand-wavey TED Talk, please!

Elon knows more about manufacturing than any other person on earth, he said

Removed by mod

Removed by mod

Link?

Removed by mod

deleted by creator

Removed by mod

Finally, an usecase for USB irons!

I just got one, and it’s so practical with a PD battery bank. Can now solder inside or outside on my car/bike with zero hazzle

I love my Pinecil. I recommend them to kids as a beginner iron cause of the low price and sleep function.

I have one too, I like the idea of it but can’t solder with it. For any serious work I use my old transformer iron that has enough power to melt the solder.

Sure, a Weller station will probably last a lifetime even with serious usage, but I do maybe…. 20 total solder joint per year, so I couldn’t justify the price.

I do agree that it’s better at what it’s supposed to do though

Not quite a Weller station, but also will last a lifetime ;)

Edit: I’m aware that USB irons are good and I’m just shit at using them

I really appreciate that you took the time to take a photo to show us your iron. It’s nice to get the more personal touch as I keep forgetting we are real people talking together.

It looks like an old clenodium. I’m sure it has seen its fair share of work. Thanks for sharing!

Don’t they have switches?

No.

Seriously, many soldering irons don’t have a switch. Fancy soldering stations have switches, temperature dials, etc. But basic ones are just a resistive load wired directly to the plug.

I think they meant on the wall or outlet not the iron.

Sounds like a cheap portable soldering iron, which just heats up to some roughly usable temperature whenever it’s plugged in.

Textbook definition!

Ive seen some really cheap irons that have zero controls, you plug them in and they operate at max power. Basically a wood burning pencil, really.

An engineer that has a project to show off at a trade show will have will have both a power switch and a temperature control on their soldering iron.

I’m an engineer that’s been in that sort of situation. If it’s planned, you have the tools. Unfortunately, sometimes these things happen and it’s not planned. At that point it’s taken what you can get. A cheap fire stick will still do the job better than no fire stick.

Every one i’ve owned has and I get the cheap ones. I guess you can find them for under a dollar or something

I’ve only seen outlet switches in the UK, unless you plugged into a roof lamp outlet where the switch are by the entrance door, but then you need a plug like these (at least here in sweden)

They need a 1/4 duty cycle.

I’ve had a similar experience as a child. I live in Germany and found this voltage switch on a hair dryer. My thoughts were like: Switching it to less couldn’t possibly hurt, could it? Well it could. It was super efficient though but only for a few seconds before it self destructed.

Person Wait Modulation.

I had the opposite problem, I brought a soldering iron from Europe to Canada, and despite using a step up transformer, it just couldn’t get hot enough to melt the solder!

You should have used 200% duty cycle

Splice on a second plug, so you can use two outlets at the same time.

(/s, mostly… this can actually work, if you can find two outlets on opposite phases.)

There’s an actual commercial product that does this. It even meets UL and CSA standards.

But it wouldn’t be 200%, it would be something like 170% power assuming 3 phases, right. Too lazy to do the math.

You’re correct, phase-to-phase is 173.2% of the phase-to-neutral voltage in 3-phase “Wye” service.

But that’s not what consumers (typically) use in North America. We don’t bring three phase to the home.

Our single-phase final distribution transformers have a center tap on the secondary coil, bonded to neutral. So, one side of the coil provides a 120v leg with respect to that neutral, and the other side provides an opposing leg, 180° from the first, and 120v with respect to that same neutral. Most of our appliances use leg-to-neutral, 120v. But leg-to-leg is 240v.

(Commercial and industrial facilities can get a wide variety of voltages in single or three phase, and we do have some actual, 2-phase generators and customers: the phases are 90° apart rather than 120° or 180°)

The technology connections video talking about 240v power mentioned some apartment buildings having 208v because they’re bringing in two phases instead of center tapping or whatever. So their comment could be right in the correct locations i think.

I’m clearly no sparky.

Correct. It’s not typical, but it does exist. 208v is usually close enough for 240v appliances.

And lots of things meant to run on 240 are dual labeled 208/240. If it’s a motor it will end up running a little hotter, if it’s a heater it will end up a little colder.

They are referring to recombining the two halves of split-phase like what is done with an outlet for an electric dryer or oven, but outside the walls.

https://theengineeringmindset.com/120-240v-split-phase-us-can/

US has two phase power in residential households

Split phase, not two phase.

Two-Phase has two legs, 90 degrees apart. When one phase is at maximum amplitude the other phase will be at zero.

Split Phase is 180 degrees apart. When one leg is at maximum positive amplitude, the other will be at maximum negative amplitude. When either is crossing zero, the other is also crossing zero, in the opposite direction.

Reminds me of the time when I helped install some 120 VAC ceiling fans and the electrician* wired them to the 220 VAC line. They spun like a helicopter trying to take off.

*Worked for the local electric utility, we trusted him, foolishly.

Hey. If it works, it works.

Any port in a storm right?

Why plug and unplug? Doesn’t the wall outlet have a switch?

I have actually never met a wall outlet with a switch.

Really? Where are you for that? I don’t have a wall outlet without a switch, and I’ve never seen one because why would it just be live all the time?

I’m in Australia for reference.

We’re the exception, most places don’t have switches on their outlets.

Germany. It’s just live all the time, because why wouldn’t it? If you plug something in, you want it to work. If you don’t want it to work, you either plug it out (which works just as well as a switch, with the same convenience), OR you use the switch at the appliance because why would you try to reach the hypothetical switch at the wall outlet if the wall outlet is behind a drawer, under a table, or whatever inconvenient place? I use my remote control to turn the TV on or off, I don’t physically walk to the wall power outlet.

I can’t turn my tv entirely off without cutting power to it because of the standby light. Same thing for my laptop. The switch is typically not hidden behind things because that is really annoying. Power switch in my room that I use is right next to my bed, can turn the light off without leaving bed.

Things that don’t get moved don’t get unplugged because why bother when you hit the switch and it’s entirely off, and actually entirely off unlike what most of my devices do when ‘off’ but powered

Keep in mind modern TVs have very low standby drain, and if it’s an OLED then unplugging it or turning off the outlet instead of letting it stay in standby will actually slowly break your panel

Tv is like 10 years old and definitely not OLED. Good information to have though.

Afaik it is a safety thing that is handled differently in different countries.

Uk and their colonised countries have this. The reason is that the fuses are in each plug. But no (or almost no) fuses in the power grid of the house. In Europe most countries have a single GFCI and several fuses for power grid sectors in a single place in the house where the power comes in.

I assume the switches on the power outlets are for turning off a switch because there is no GFCI in the house.

I think in the UK at least this view might be a little outdated - every house I’ve ever lived in has had GFCI sectors across the house, or had to be updated to have it when work was done.

Well I would need to do research on that so I can make actual claims here, but I think the switches on the power outlets are somewhat related to the kind of how fuses are handled.

I think it’s mostly due to the the way the “ring mains” are often wired in UK to basically cheapout of copper I think . . .

The consumer unit/fusebox/gfci protects the whole ring mains wire from overheating or ground leakage - up to the socket - but that will likely be more current than any individual appliance would want to see maybe 20A or 32A or something. So it’s up to the appliance to protect itself (and its wiring from the plug) from overcurrent scearios per its own tolerances.

So we’ve officially gone meta around here lol, we did it Lemmy!